T-Shirt

2D or 3D: Which Shirt is Right for You?

The world of fashion has witnessed a remarkable evolution, with advancements in technology transforming the way clothing is designed and produced. One such innovation is the emergence of 3D printing technology, which has revolutionized the apparel industry. This cutting-edge technology enables the creation of intricate and personalized garments that were once unimaginable. In contrast, traditional 2D printing techniques have been the industry standard for decades, relying on flat designs and limited customization options.

This article delves into the key differences between 2D and 3D shirts, exploring the technical aspects, visual impact, market dynamics, and environmental considerations associated with each approach. By understanding the unique characteristics of these two methods, we can appreciate the potential of 3D printing to shape the future of fashion.

2D vs. 3D Shirts: A Technical Deep Dive

The realm of fashion has witnessed a transformative shift, largely driven by technological advancements. One such innovation is the burgeoning field of 3D printing, which has revolutionized the way we design and manufacture garments.

Technical Differences

At the core of 2D and 3D shirts lies the fundamental difference in their production techniques. 2D shirts, the traditional approach, rely on planar printing methods like screen printing, digital printing, or heat transfer. These techniques involve transferring ink or dye onto a flat fabric surface, limiting the design to two dimensions. In contrast, 3D printing employs additive manufacturing processes, building objects layer by layer from a digital design. This allows for the creation of intricate, three-dimensional structures, providing unparalleled flexibility and customization options.

The choice of materials also distinguishes 2D and 3D shirts. 2D shirts typically utilize conventional fabrics like cotton, polyester, or blends, with the selection often constrained by the printing technique. 3D printing, however, offers a wider range of material possibilities, including thermoplastic polymers, elastomers, and even biomaterials. This versatility enables the creation of garments with unique textures, shapes, and functionalities, expanding the boundaries of fashion design.

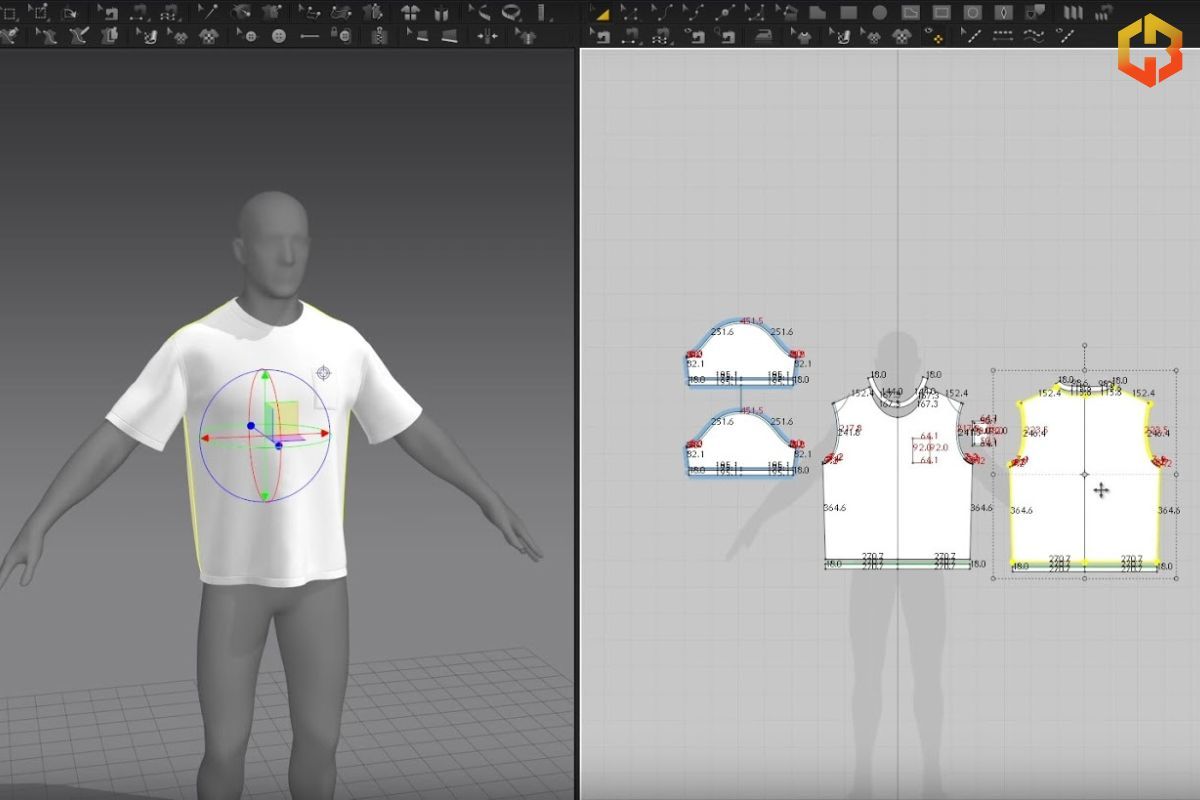

The design process for 2D and 3D shirts also differs significantly. 2D designs are traditionally created using flat patterns, which are then cut and sewn together. This approach is limited by the constraints of two-dimensional design software, often restricting the complexity and creativity of the design. 3D printing, on the other hand, leverages advanced 3D modeling software to create complex, three-dimensional designs. This allows for greater freedom of expression and the exploration of innovative design concepts.

Visual and Aesthetic Differences

The visual impact of 2D and 3D shirts is starkly different. 2D shirts, by their nature, produce flat, two-dimensional designs. While skillful use of shading, gradients, and patterns can create the illusion of depth and texture, the overall visual experience remains limited. 3D printing, however, enables the creation of intricate, three-dimensional designs that offer a more immersive and visually striking experience.

The perception of depth and texture is another key distinction between 2D and 3D shirts. 2D printing techniques can simulate depth and texture, but they are often limited in their ability to create realistic tactile sensations. In contrast, 3D printing can directly create physical textures and patterns on the surface of the garment, providing a more authentic and sensory experience.

Customization and personalization are also significantly different between the two approaches. 2D printing offers limited customization options, typically involving variations in color, size, and simple design modifications. 3D printing, on the other hand, enables highly personalized garments, tailored to individual preferences and body measurements. This allows for the creation of unique, one-of-a-kind designs, catering to the growing demand for individuality and exclusivity.

Market and Consumer Differences

The target market for 2D and 3D shirts differs significantly. 2D shirts, as a traditional and widely available product, appeal to a broad range of consumers, including those seeking affordable, mass-produced garments. 3D printing, on the other hand, targets niche markets, such as high-end fashion, sports apparel, and medical applications. It attracts consumers who value innovation, customization, and exclusivity.

The pricing and market positioning of 2D and 3D shirts also vary. 2D shirts are generally more affordable due to economies of scale and standardized production processes. They are often positioned as mass-market, everyday wear. 3D printed shirts, on the other hand, are often more expensive due to the higher costs of 3D printing technology and specialized materials. They are typically positioned as premium, luxury, or high-performance apparel.

Consumer perception and brand image are also influenced by the use of 2D and 3D printing. 2D printing is associated with traditional fashion and mass-market brands, perceived as conventional and mainstream. 3D printing, on the other hand, is associated with innovation, technology, and futuristic design, perceived as cutting-edge and exclusive.

2D shirts featuring Rose from BLACKPINK are popular among fans.

Environmental and Ethical Considerations

The environmental and ethical implications of 2D and 3D printing also differ. 2D printing can have significant environmental impacts, including water pollution, chemical waste, and greenhouse gas emissions. The specific environmental impact depends on the printing techniques and materials used. 3D printing, on the other hand, offers potential for more sustainable production, with reduced waste and energy consumption. However, the environmental impact can vary depending on the materials and processes used.

The ethical production of 2D and 3D shirts is another important consideration. 2D printing relies on traditional manufacturing processes, which can be associated with labor exploitation and poor working conditions. Careful monitoring and ethical sourcing of materials are essential to ensure responsible production. 3D printing, on the other hand, can be more easily localized and decentralized, reducing the reliance on global supply chains. This offers opportunities for fair trade and ethical production practices.

In conclusion, 2D and 3D printing technologies offer distinct advantages and disadvantages, catering to different market segments and consumer preferences. While 2D printing remains a dominant force in the fashion industry, 3D printing has the potential to revolutionize the way we design, produce, and consume clothing. By understanding the key differences between these two approaches, we can appreciate the future of fashion and the exciting possibilities that lie ahead.

2D vs. 3D Shirts: A Comparative Table

This table provides a concise overview of the key differences between 2D and 3D shirts, covering aspects such as production techniques, materials, design process, visual impact, customization, market positioning, and environmental and ethical considerations.

| Feature | 2D Shirts | 3D Shirts |

| Printing Technique | Screen printing, digital printing, heat transfer | Additive manufacturing (3D printing) |

| Material | Cotton, polyester, blends | Thermoplastic polymers, elastomers, biomaterials |

| Design Process | Flat pattern design, cutting, sewing | 3D modeling software, layer-by-layer construction |

| Visual Impact | Flat, two-dimensional designs | Intricate, three-dimensional designs |

| Depth and Texture | Simulated depth and texture | Physical depth and texture |

| Customization | Limited customization options | High degree of customization |

| Target Market | Mass market | Niche markets (high-end fashion, sports apparel, medical) |

| Pricing | More affordable | More expensive |

| Environmental Impact | Potential for significant environmental impact | Potential for more sustainable production |

| Ethical Considerations | Relies on traditional manufacturing processes | Can be more easily localized and decentralized |

Conclusion

In conclusion, 2D and 3D printing technologies offer distinct advantages and disadvantages, catering to different market segments and consumer preferences. While 2D printing remains a dominant force in the fashion industry, 3D printing has the potential to revolutionize the way we design, produce, and consume clothing. By understanding the key differences between these two approaches, we can appreciate the future of fashion and the exciting possibilities that lie ahead.

10 FAQs About 2D and 3D Shirts

What is the difference between a 2D and a 3D shirt?

- 2D shirts are traditional garments with flat, two-dimensional designs printed or embroidered onto the fabric.

- 3D shirts utilize advanced printing techniques to create three-dimensional structures and textures on the fabric’s surface.

How is 3D printing used to create shirts?

3D printing involves layering materials to build up a three-dimensional object. In the case of shirts, this can be used to create intricate patterns, textures, and even raised designs.

What are the advantages of 3D printed shirts?

- Unique designs: 3D printing allows for highly customized and unique designs.

- Enhanced comfort: 3D printing can create garments with specific fits and textures.

- Improved durability: 3D printed fabrics can be more durable and resistant to wear and tear.

Are 3D printed shirts more expensive than 2D shirts?

Currently, 3D printing technology is more expensive than traditional 2D printing methods. However, as technology advances, prices are expected to decrease.

Are 3D printed shirts environmentally friendly?

The environmental impact of 3D printing can vary depending on the materials and energy used. However, 3D printing can reduce waste and minimize the need for excessive material usage.

Are 3D printed shirts comfortable to wear?

3D printed shirts can be incredibly comfortable, as they can be tailored to the wearer’s specific body shape and preferences.

Can I customize a 3D printed shirt?

Yes, 3D printing offers a high degree of customization, allowing you to create unique designs and incorporate personal touches.

How do I care for a 3D printed shirt?

Care instructions for 3D printed shirts may vary depending on the specific materials used. However, generally, gentle hand washing and air drying are recommended.

What is the future of 3D printed fashion?

The future of 3D printed fashion is promising. As technology continues to advance, we can expect to see more innovative and sustainable 3D printed garments.

Where can I buy a 3D printed shirt?

While 3D printed fashion is still a relatively niche market, you can find 3D printed shirts from various online retailers and designers.

Read More:

What T-Shirt Color is Most Popular?